Coatings, Free Full-Text

4.7 (499) In stock

Inconel 718 alloy has a wide range of applications in the aerospace sector because of its superior mechanical properties and its weldability. The machining of such higher strength materials with complex shapes is possible with wire electrical discharge machining. In the present research, an endeavor was made to enhance the machining process by utilizing zinc-diffused coating brass wire electrode and Taguchi-Data Envelopment Analysis-based Ranking (DEAR) methodology in the process while machining Inconel 718 alloy. Material removal rate, kerf width, and surface roughness were considered as the quality measures. The optimal arrangement of input factors in the Wire Electrical Discharge Machining (WEDM) process were found as 140 µs (Ton), 50 µs (Toff), 60 V (SV), and 5 kg (WT) among the elected factors with the error accuracy of 1.1%. The pulse-off time has the most significance on formulating the quality measures owing to its importance on deionization in the process.

Environmentally Friendly Chemical Resistant Solvent Free Epoxy

Eyeglass Coating Types, Making the Right Choice

Coating-Composite and Functional Filter Material/Filter Rolls

Coatings, Free Full-Text

Beyond Paint

Coatings, Free Full-Text

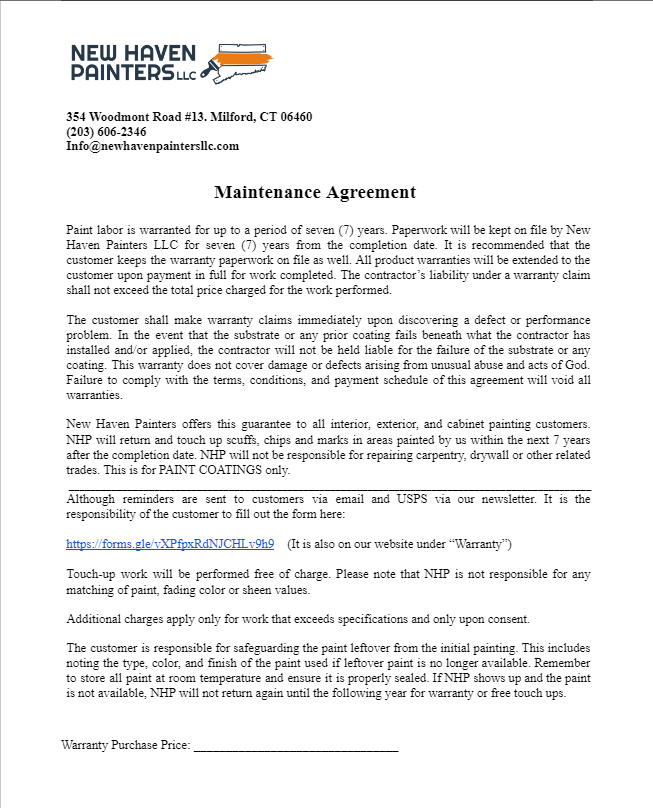

Painter Warranty, New Haven Painters LLC

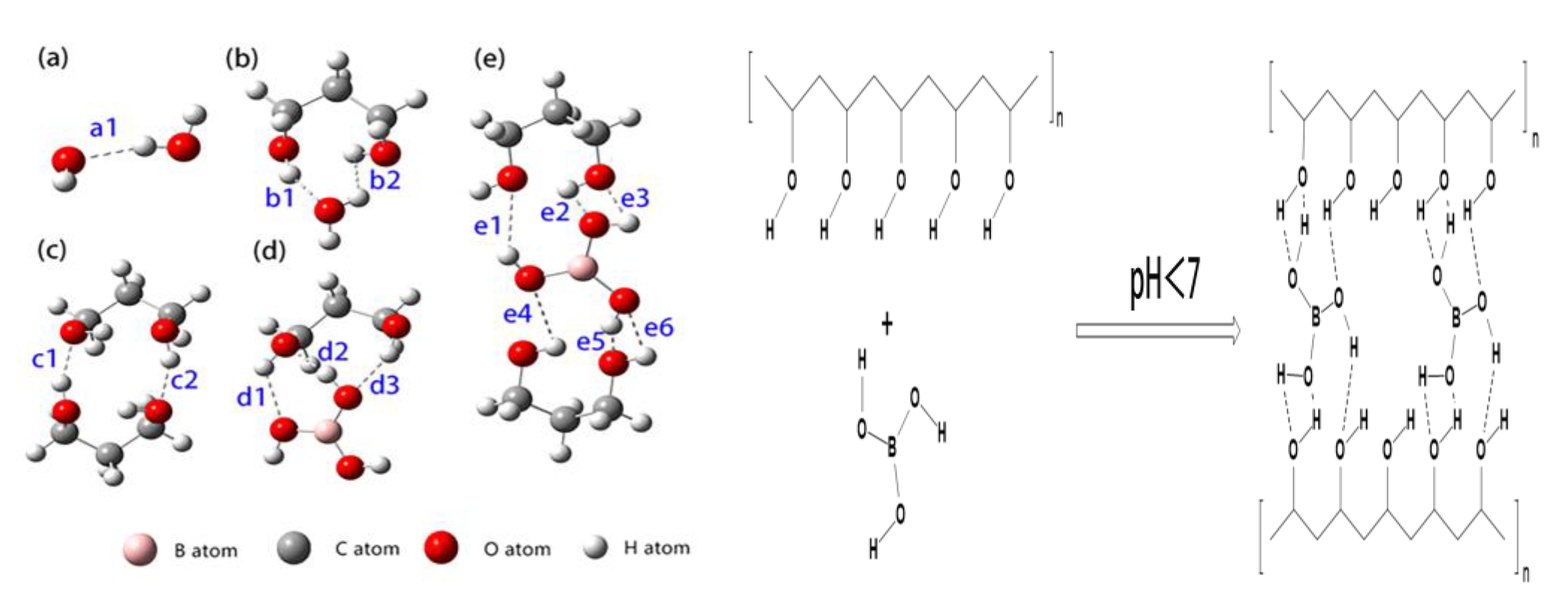

PVA/Poly(hexamethylene guanidine)/Gallic Acid Composite Hydrogel

2-(3,4-Epoxy) ethyltriethoxysilane-modified waterborne acrylic

Coatings, Free Full-Text

What does Solvent Free epoxy mean?!

factory direct wire cut edm brass

Sac à main noir

Sac à main noir 190mamelons_coniques Conical nipples - Pneumatic

190mamelons_coniques Conical nipples - Pneumatic Harley Davidson Sportster Model Tank Editorial Image - Image of gasoline, brand: 143443705

Harley Davidson Sportster Model Tank Editorial Image - Image of gasoline, brand: 143443705:fill(white):quality(80)/https://www.agentprovocateur.com/static/media/catalog/product/2/8/109698_flatshot_front.jpg) Dion Balconette Multiway Sculpting Bra in White | Agent Provocateur

Dion Balconette Multiway Sculpting Bra in White | Agent Provocateur Safort 19 21 23 Inseam Regular Tall High Waist Capri Bootcut Yoga Pants with Pockets Black S : Clothing, Shoes & Jewelry

Safort 19 21 23 Inseam Regular Tall High Waist Capri Bootcut Yoga Pants with Pockets Black S : Clothing, Shoes & Jewelry Brasil x Suíça ao vivo: como assistir o jogo do Brasil online e de

Brasil x Suíça ao vivo: como assistir o jogo do Brasil online e de